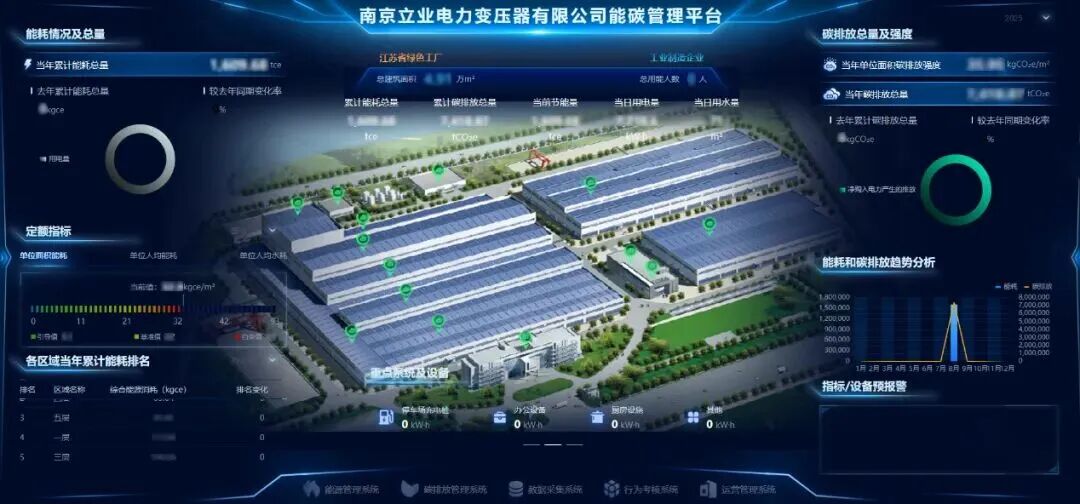

Nanjing Liye has proactively advanced its digital energy and carbon management transformation in response to the national ‘dual carbon’ strategy. By focusing on multiple dimensions including platform development, data collection, and model construction, the company has established an end-to-end green development system, ultimately achieving a series of landmark outcomes.

I. Core Initiatives Deliver Tangible Results

Guided by the principles of precision, digitalisation, and full lifecycle management, Nanjing Liye has implemented five key actions to drive tangible outcomes in its green transformation:

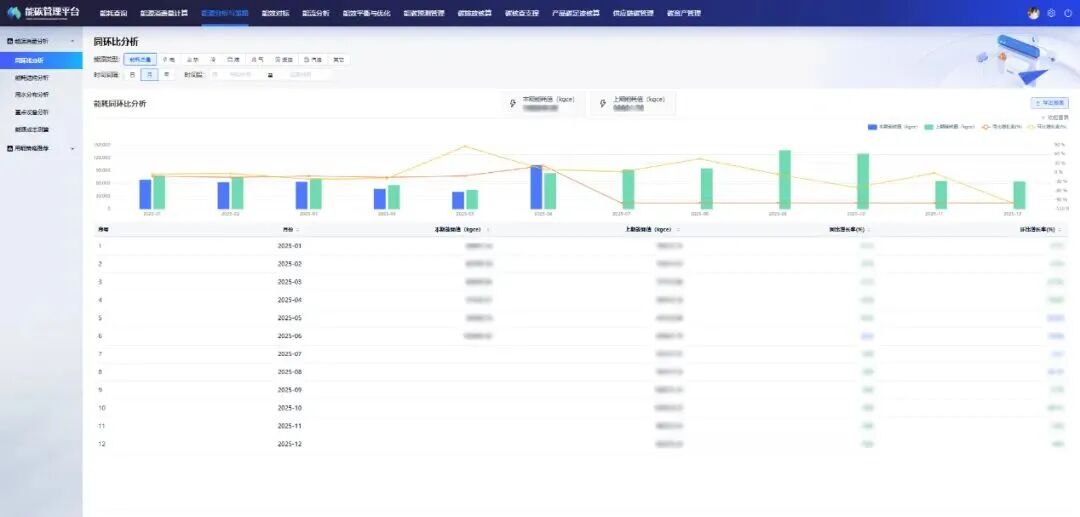

1. Established a dual-compliance energy and carbon management platform encompassing 12 core functions, including energy consumption analysis, carbon accounting, and product carbon footprint assessment, enabling fully automated end-to-end management;

2. Implementing a ‘three-tier metering system combined with IoT sensing’ for precise data collection, achieving comprehensive coverage from overall plant energy consumption down to equipment-level data;

3. Establish an integrated model linking energy consumption, carbon emissions and production efficiency to precisely identify energy consumption vulnerabilities and dynamically calculate carbon emissions.

4. Establish a green demonstration line integrating photovoltaic power generation with energy storage, optimising production scheduling to minimise idle energy consumption;

4. Establish a green demonstration line integrating photovoltaic power generation with energy storage, optimising production scheduling to minimise idle energy consumption;

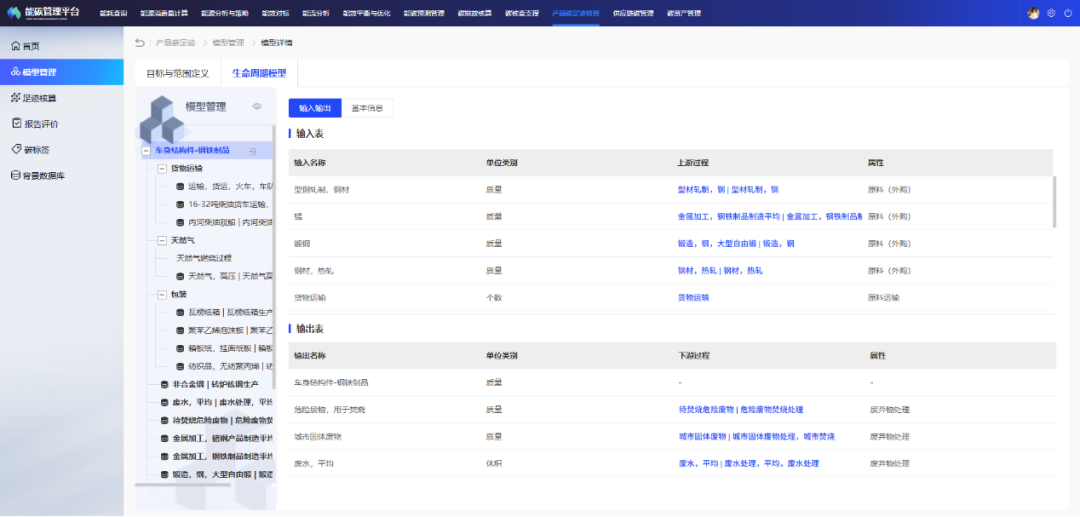

5. Launch a dual-pronged carbon footprint reduction initiative encompassing both organisational and product dimensions, calculating emissions in accordance with national standards while optimising low-carbon product design.

5. Launch a dual-pronged carbon footprint reduction initiative encompassing both organisational and product dimensions, calculating emissions in accordance with national standards while optimising low-carbon product design.

II. Core Achievements: Setting Industry Benchmarks for Low-Carbon Practices

II. Core Achievements: Setting Industry Benchmarks for Low-Carbon Practices

Significant Achievements: Precision Carbon Management Delivers Enhanced Comprehensive Benefits

Through systematic digital transformation, Nanjing Liyi has achieved remarkable results:

- The proportion of data automatically collected by metering instruments increased from 3% to 99.6%, reducing carbon emission calculation error rates to within ±1%.

- High-precision data pinpointed energy leakage issues in equipment such as air compressors, yielding substantial energy cost savings.

- Eliminating manual meter reading errors reduced monthly carbon emissions report generation time from 7 days to under 1 minute, enabling rapid response to carbon management strategies.

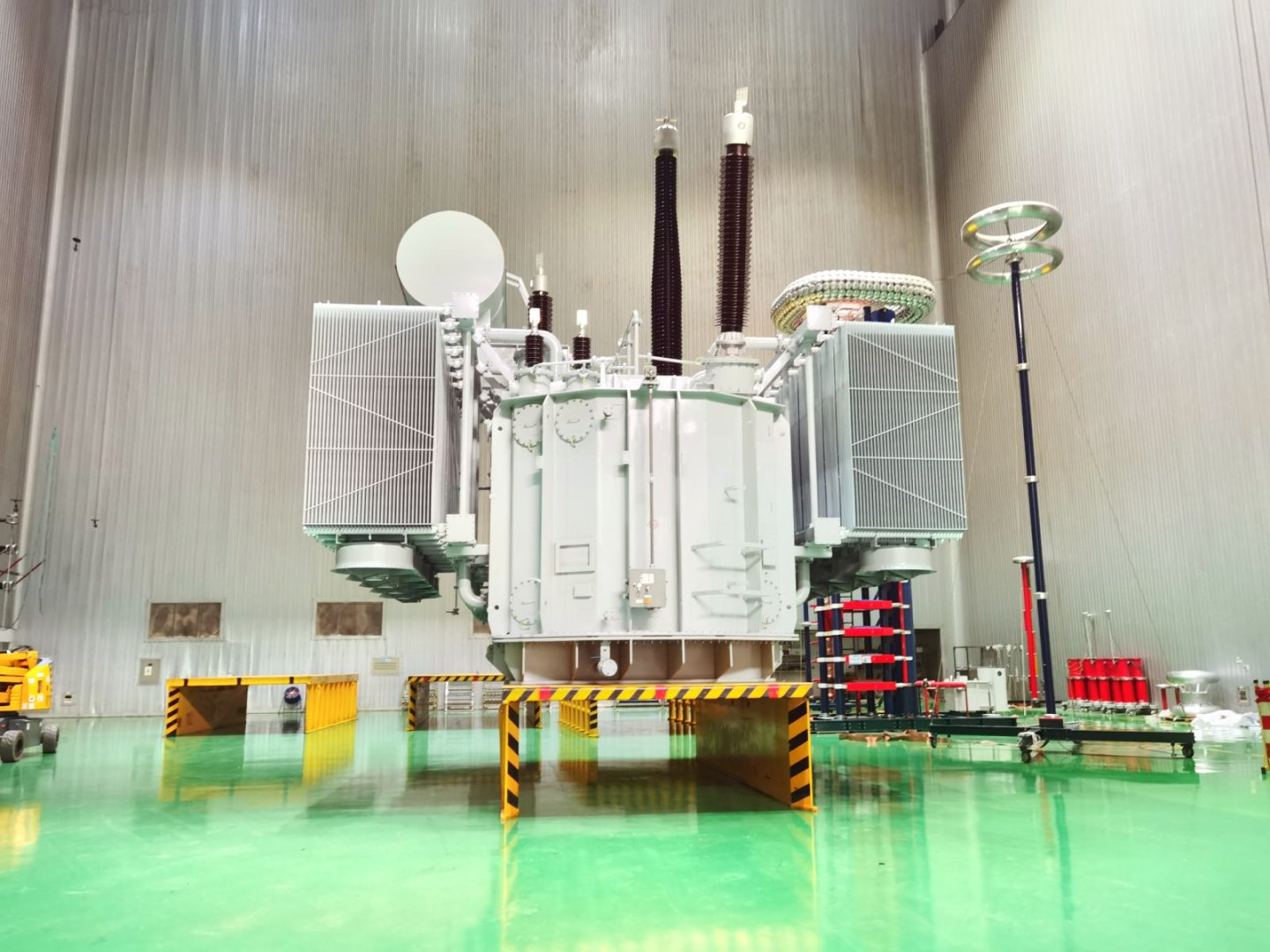

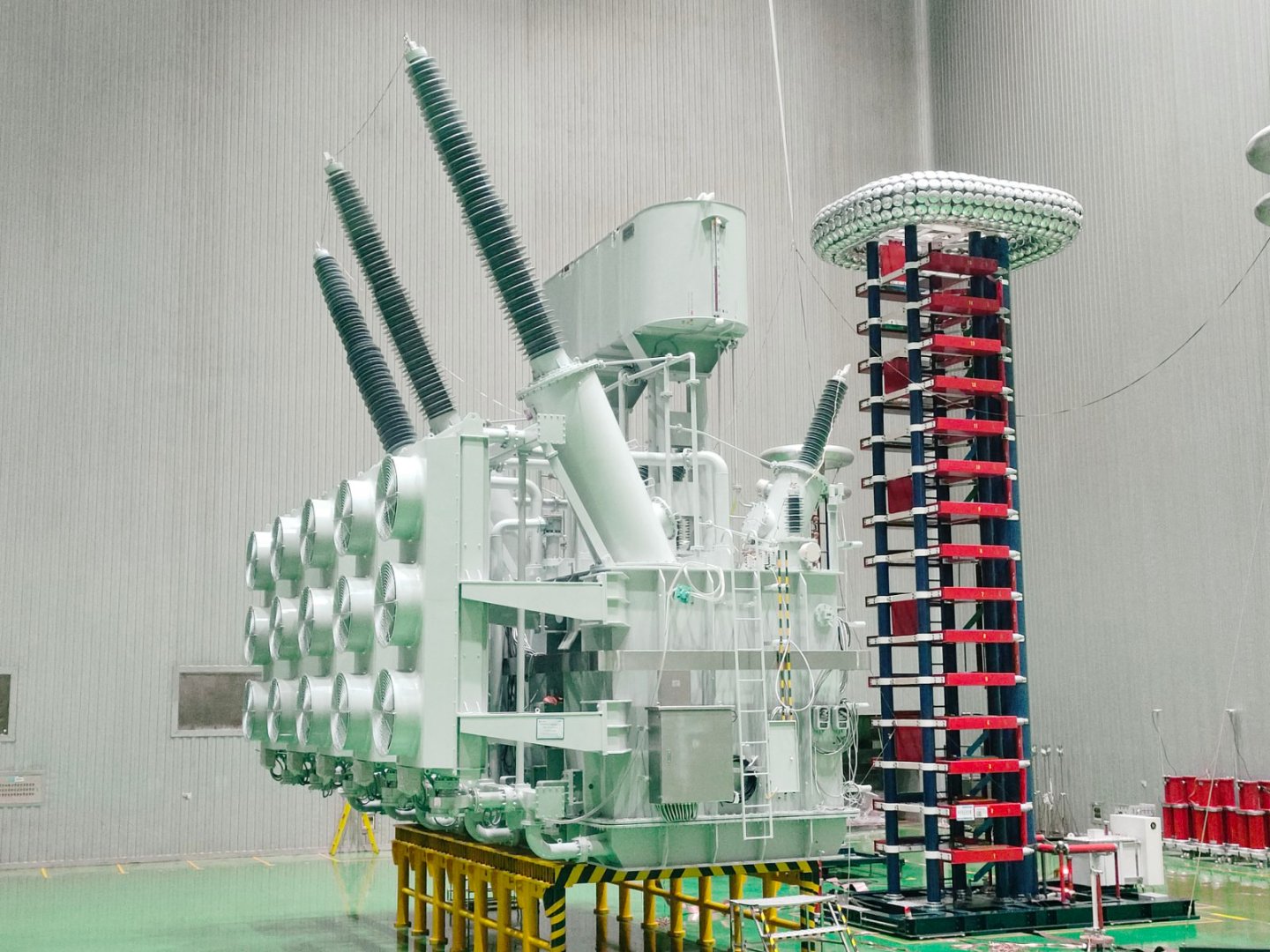

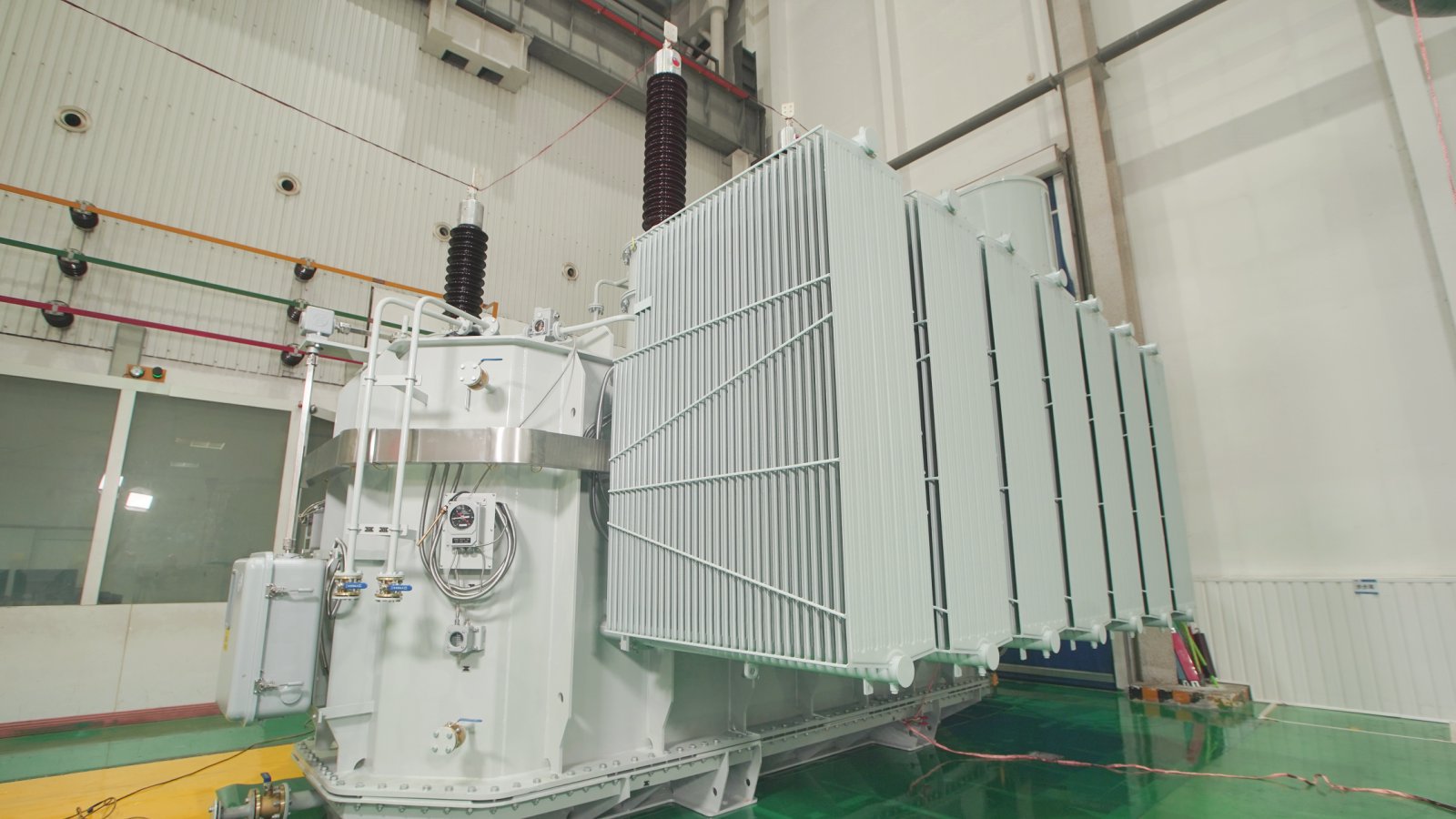

- Implemented full lifecycle management of transformer product carbon footprints. Rapidly matched metered data with production process data, enhancing calculation accuracy and convenience while reducing product carbon emissions.

- Integrated energy efficiency benchmarking with production optimisation, lowering energy consumption per unit of output.

- Achieved annual electricity savings exceeding 6 million kWh, reducing carbon emissions by over 3,200 tonnes and generating significant comprehensive benefits for the enterprise.

Moving forward, Nanjing Liye will continue to deepen its green transformation, establishing energy and carbon management capabilities as a key component of the enterprise’s new productive forces. We shall persist in spearheading the industry’s green and low-carbon development, contributing further corporate strength towards achieving the dual carbon goals.