About Us

About LiYe——Powering

Progress in Core Sectors

Shenzhen Liye Group Co., Ltd., founded in 1995 and headquartered in Shenzhen, is a comprehensive industrial holding group with a registered capital of 10 billion yuan. Adhering to a business philosophy of “integrity, loyalty, and professionalism,” the group has long pursued an “industry + finance” model. It focuses on value-oriented operations and industrial value creation, with businesses spanning power equipment manufacturing, new energy, chemical industry, biomedicine, and finance. The group operates more than 100 controlled and equity-holding subsidiaries, forming a nationwide and overseas network that contributes positively to social employment.

Mature business model and diversified industrial layout.

Large-scale operation volume and extensive network coverage.

About Us

The factory was established and named Nanjing Power Transformer Factory

First export, 20MVA/132kV exported to Pakistan

Passed the quality, environment, occupational health and safety management system certification; passed the PCCC China Electric Power Product Certification

Awarded as Jiangsu Province High-tech Enterprise; Awarded as Jiangsu Province Ultra-high Voltage Power Transformer Engineering Technology Center

SFSZ11-180000/220 products have passed the test of the National Transformer Quality Supervision and Inspection Center (including sudden short-circuit test)

Won the second prize of scientific progress of State Grid Jiangsu Electric Power Company

SWZ22-RL-10000-35 first-class energy-efficient natural ester insulating oil power transformer was independently developed; awarded as Jiangsu Province's specialized, refined, special and innovative small and medium-sized enterprise

ODFS22-334000/500-NX1 first-level energy-efficient transformer passed the test of the National Transformer Quality Inspection and Testing Center (including sudden short-circuit test)

DEKRA Type Test Certificate

Certification of Conformity

ASTA Type Certificate

Green Power Certificate

Green Design Product Certificate

Green Packaging Certificate

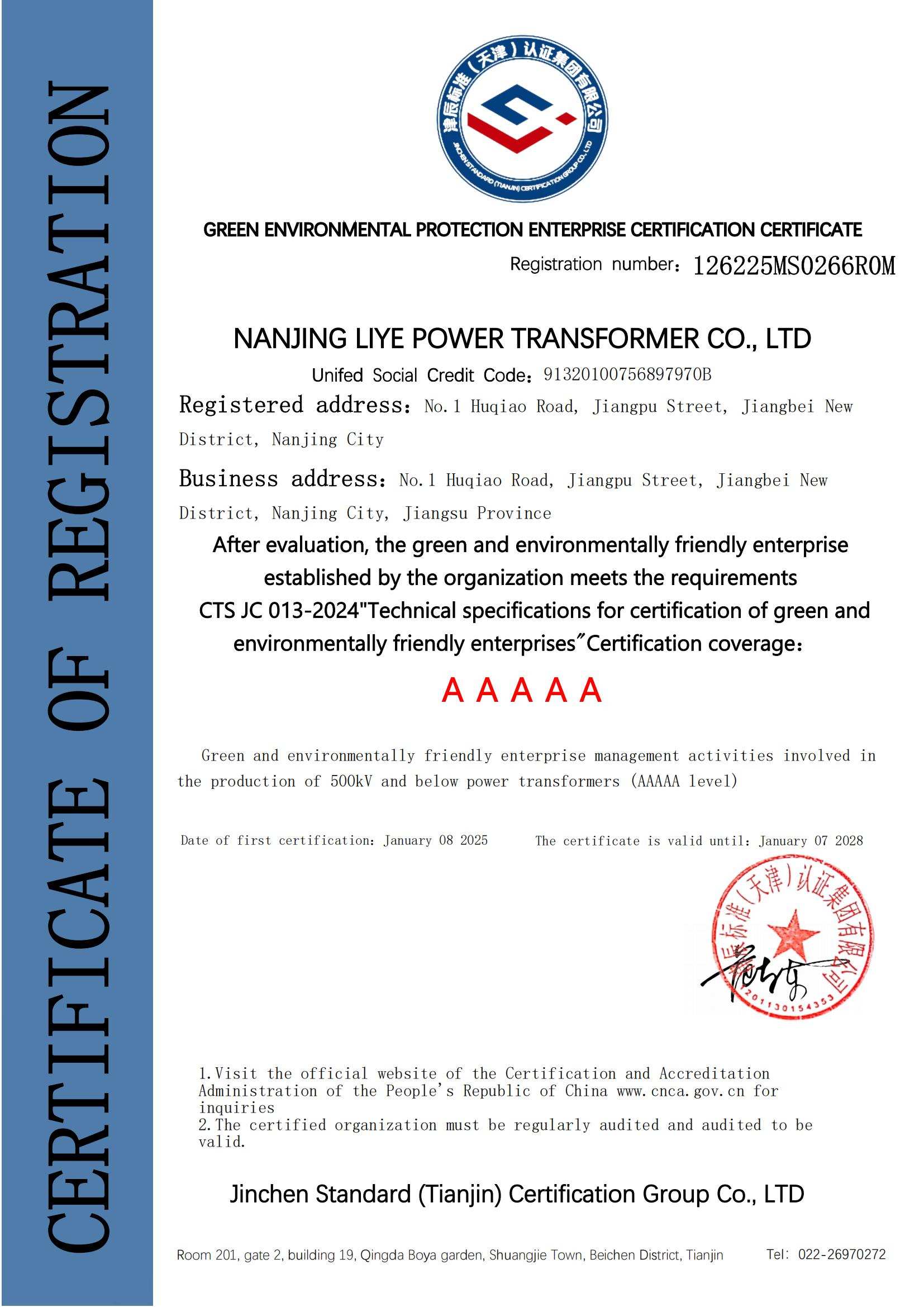

Green&Eco-Friendly Enterprise Certification Certificate

Green Supply Chain Certificate

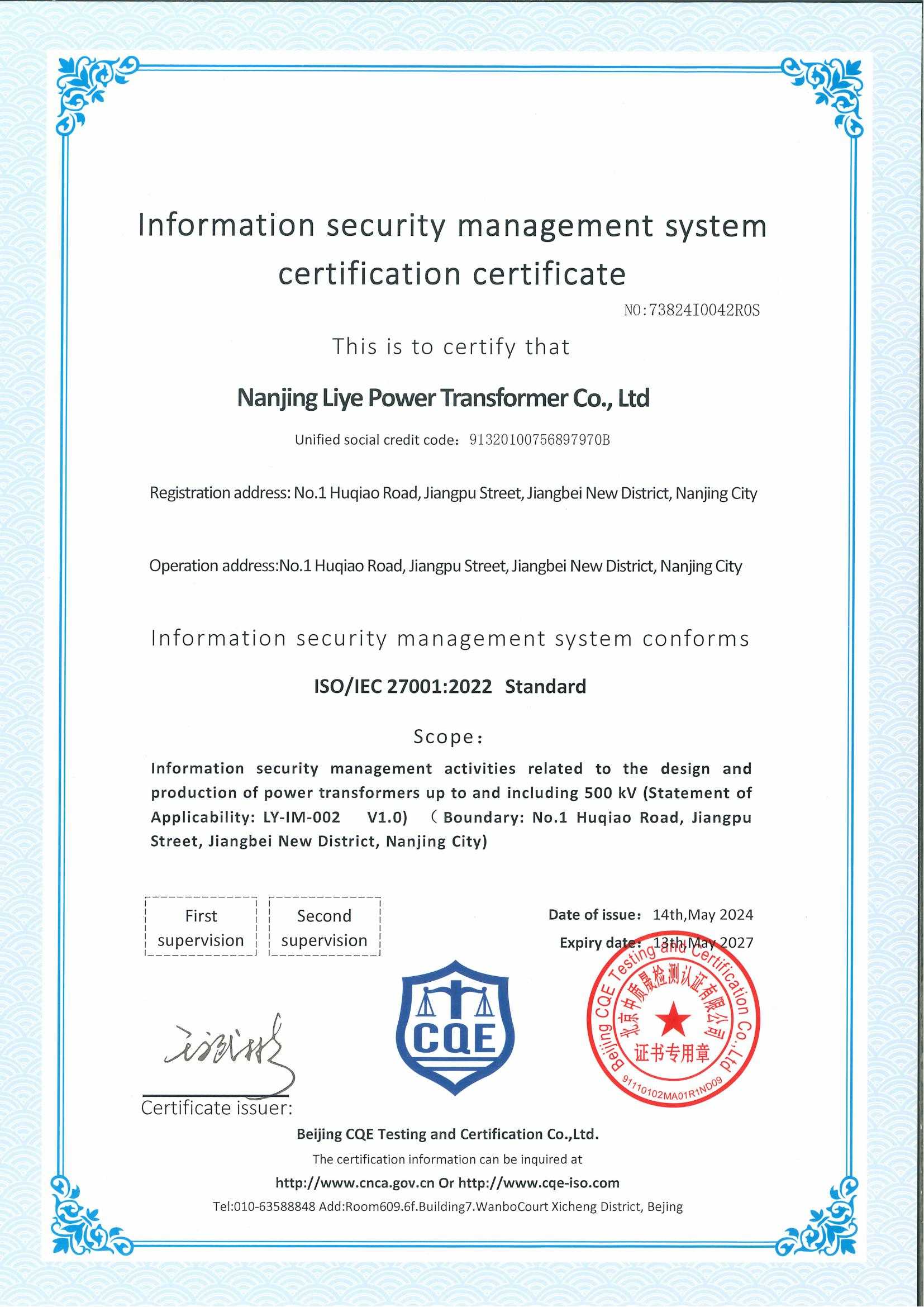

ISMS Certification Certificate

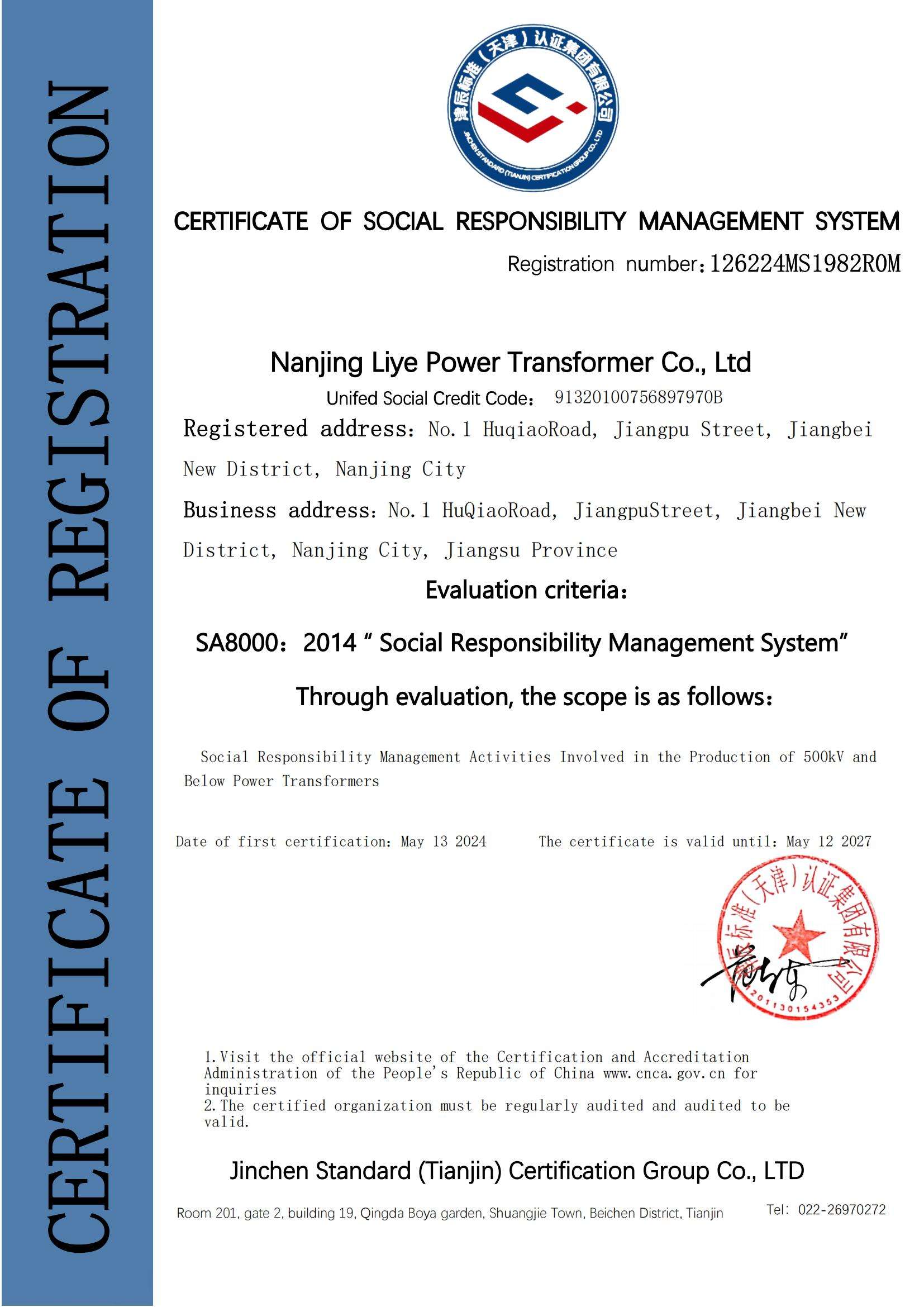

Social Responsibility Management System Certification Certificate

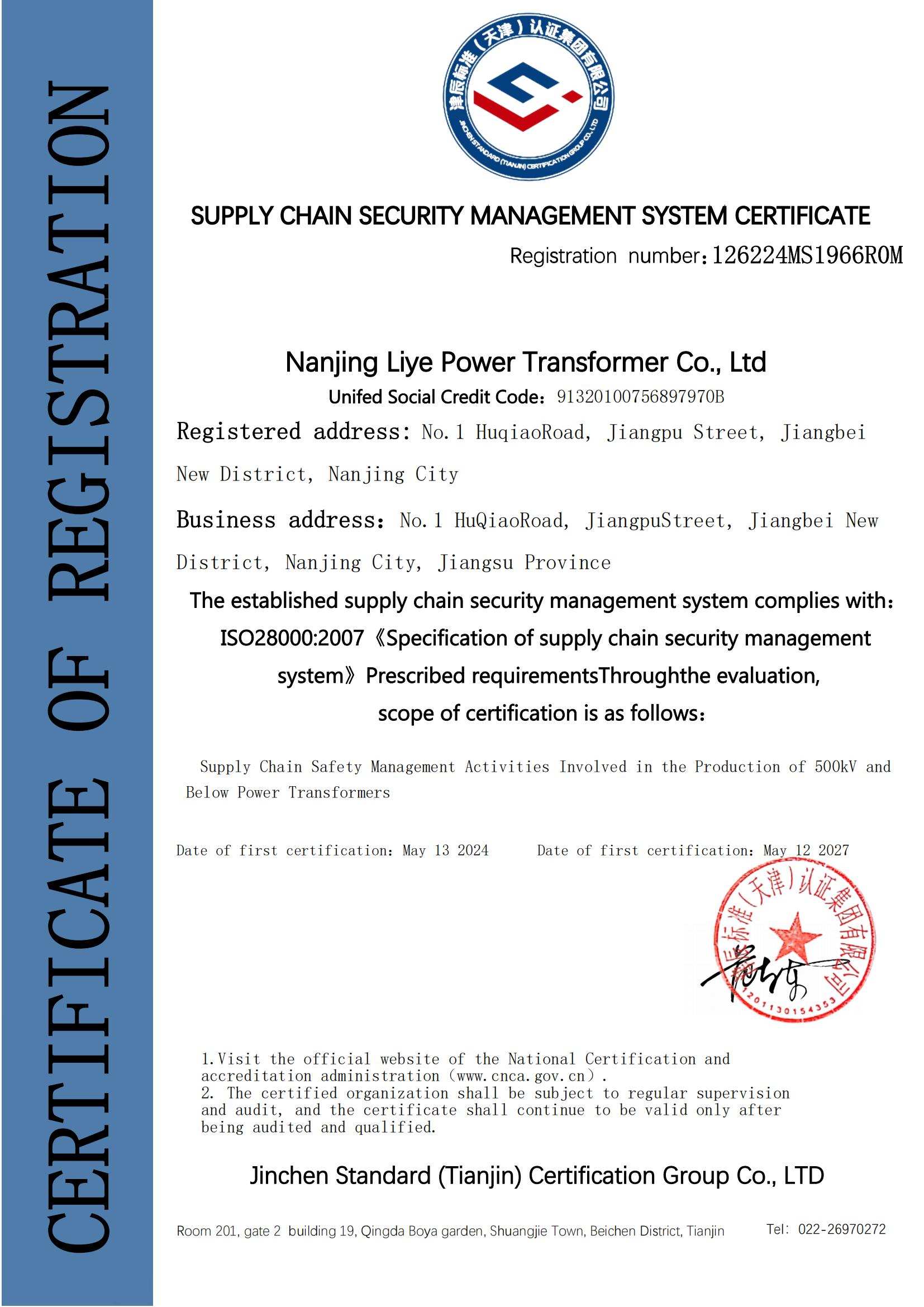

Supply Chain Security Management System

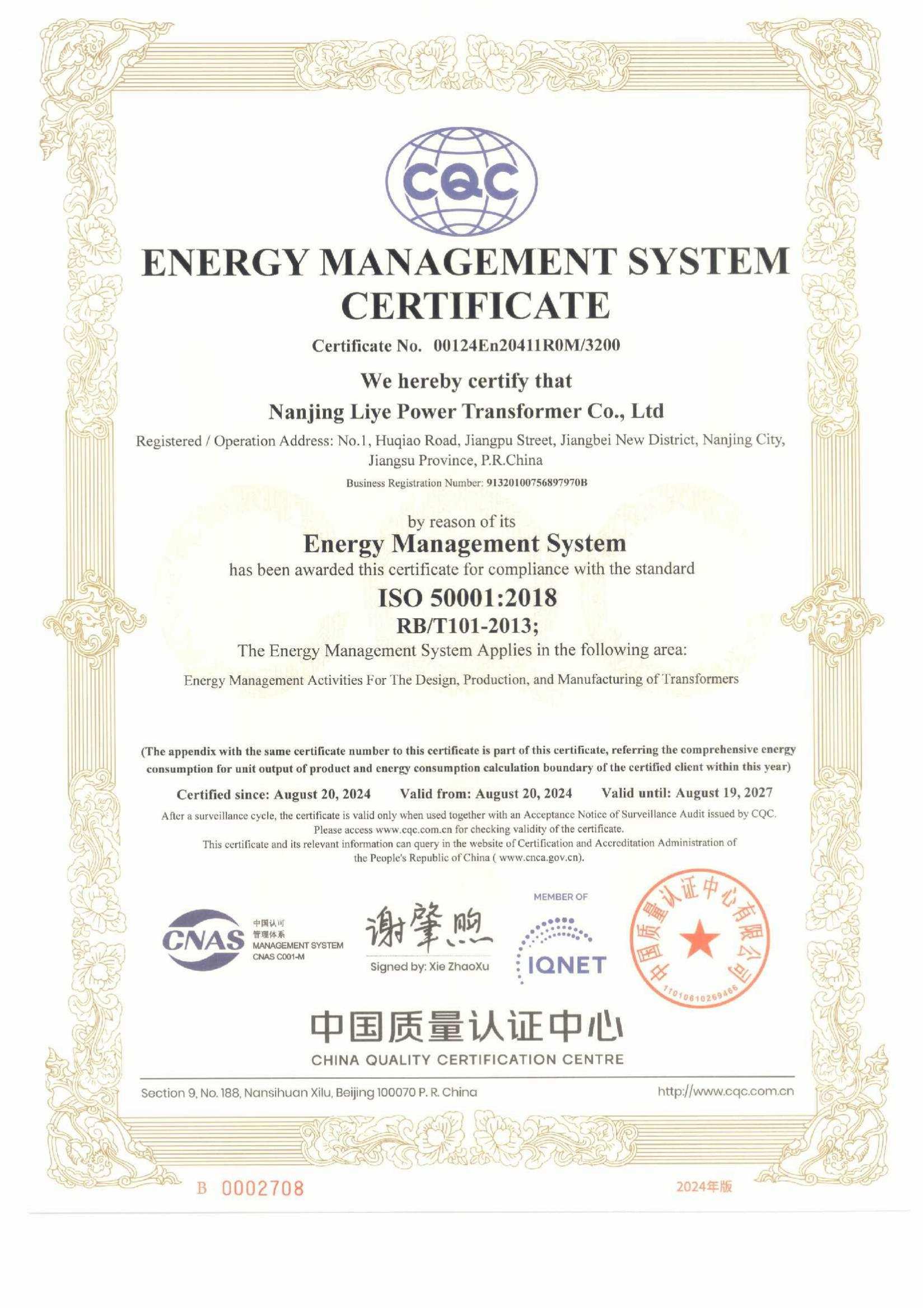

Energy Management System

Energy Management System

Jiangsu Engineering Research Center Approved Enterprise for manufacturing EHV Power Transformers

_副本.jpg)

Jiangsu Specialized & Innovative Small-Medium Enterprise Certificate

_副本.jpg)

Official Certifications

Credit Rating Certificate

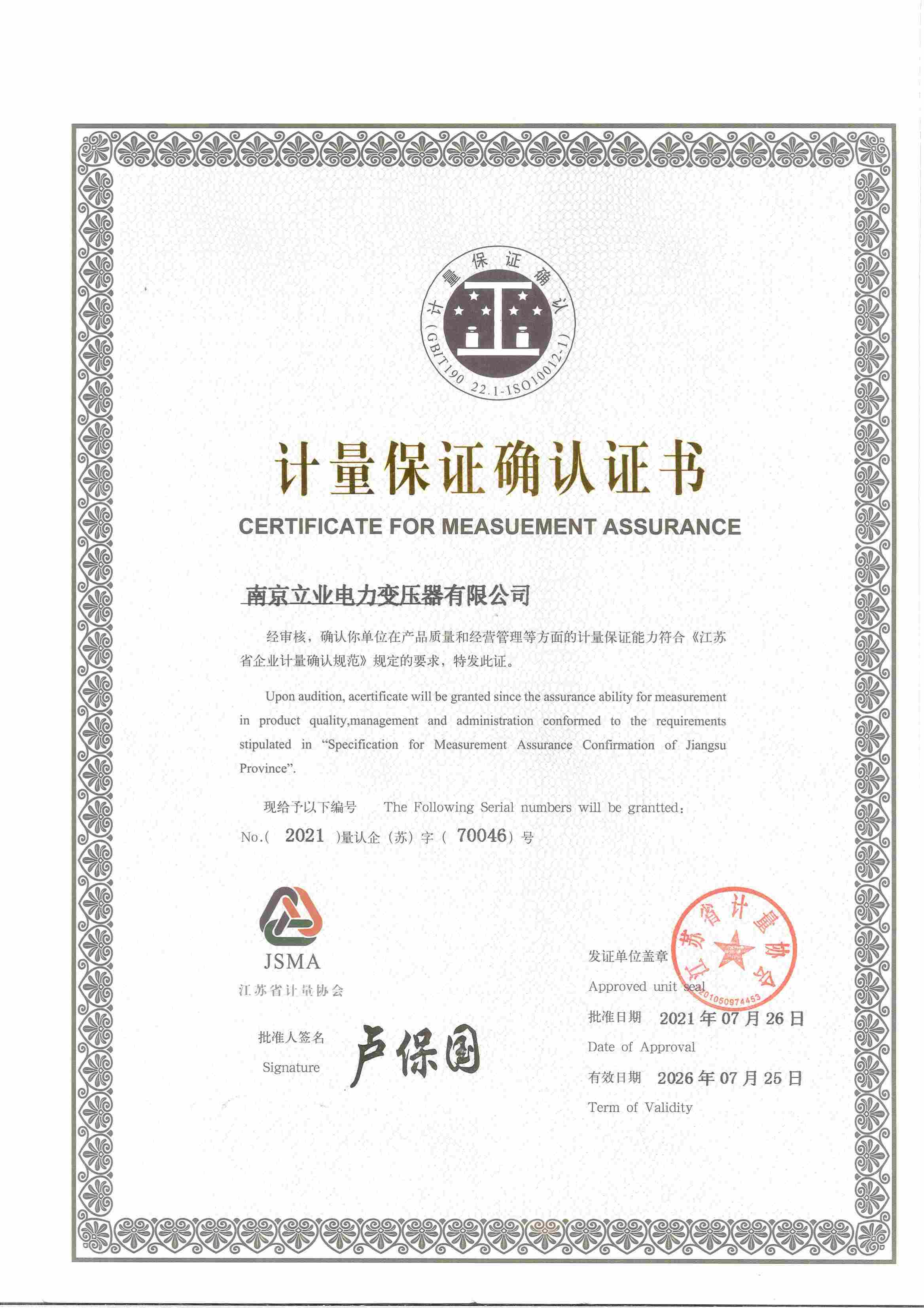

Certificate For Measurement Assurance

Adopting International Standard Product Marking Certificate

_副本.png)

Jiangsu Province Private Technology Enterprises

Transformer Production

and R&D Capabilities

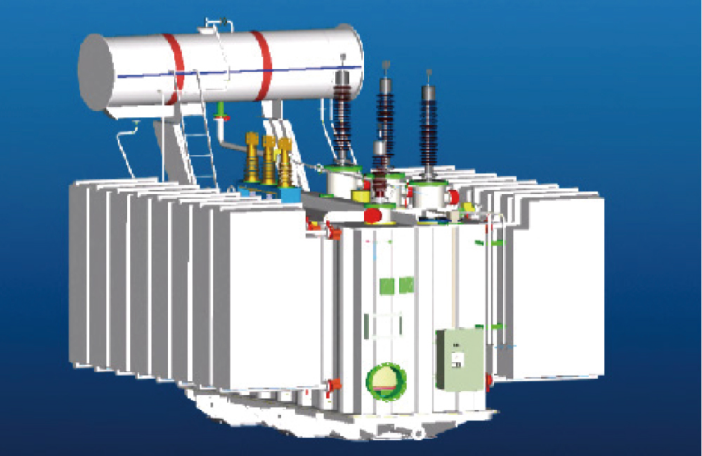

Shenzhen Live Group subsidiary (acquired 2004): we lead in high-voltage transformer tech, focusing on R&D, manufacturing & full-lifecycle management of up to 750kV units. US$40M registered capital, based in Nanjing Jiangbei New Area (multimodal transport). Over 700 staff (200+ technical). Shenzhen Live Group has honors: “China Top 500 Enterprises”, “China Top 500 Manufacturing Enterprises”, “China Top 500 Private Enterprises”, “China Top 500 Brands”.

Technical Features

- Low no-load losses

- Low load losses

- Low noise

- Low partial discharge

- Excellent short-circuit resistance

- Localised overheating prevention technology

- Reliable construction and superior seismic resistance

R&D Center

Nanjing Live Power Transformer R&D Center leads energy transmission innovation, focusing on high-efficiency transformers, smart grid integration & eco-friendly solutions. Univ collaborations drive core tech R&D, securing national patents & aiding global energy standards. We prioritize innovation: developing ultra-high-voltage solutions, precision manufacturing & predictive maintenance for better performance & longevity.

Smart Manufacturing

Insulation Manufacturing Center

Insulation Manufacturing Center

We craft every insulation part with top-grade materials and modern machines, ready for transformers up to 750 kV.

*NC-3535TC Gantry-type 4-axis CNC Machining Center.

*LM3-CNC-3030 Heavy-Duty Gantry-Type 3-Axis CNC Drilling & Milling Center

*MJWS-6312 Horizontal Panel Saw

Winding manufacturing center

Winding manufacturing center

We utilize advanced automated equipment and winding techniques for transformer manufacturing and assembly, to meet the production requirements for transformers up to 750kV.

*4000kN CNC Coil Press Machine

*VW-40 Vertical vertical VFD winding machine

*HW-10 Horizontal VFD winding machine

Oil Tank Manufacturing Center

Oil Tank Manufacturing Center

We employ precision welding technologies and advanced CNC equipment to manufacture key metal components including transformer tanks, conservators and core clamps, to meet the production requirements for transformers up to 750kV.

*FCP8025-GI (12000) Fiber Laser Cutting Machine

*WE67K-800/8000 CNC Press Brake

*G13030 Fiber Laser Cutting Machine

*Automation welding machine

Core Manufacturing Center

Core Manufacturing Center

We produce transformer cores by using advanced core stacking technology and precision cutting line processes, to meet the production requirements for transformers up to 750kV

*TBA-1000s Germany Georg Cutting Line

*CAZJ-1250-10t/5t CNC Silicon Steel Slitting Line

*200t Core Turning Machine

Assembly Center

Assembly Center

We adopt modular assembly processes, implements strict manufacturing standards and inspection procedures to ensure precision in insulation, mechanical stability, and electrical performance for transformers manufactured up to 750kV.

*VPD-600 Vapor Phase Drying (VPD) Equipment

*W1000ZH Transformer Transport Vehicle

*300t, 100t, 50t Konecranes (Finland) Overhead Cranes

Testing Center

Testing Center

The testing hall covers a area of 42m*40m*36m with hexagonal electromagnetic shield, it comes with the following advantages:

- Shield effectiveness: ≥70dB by using perforated acoustic panels

- Partial discharge background: <1pC

- Grounding resistance: ≤0.5Ω

- Reverberation time: <2 seconds (within the frequency range of 100-5000Hz)

Send Us A Message

- No.1 Huqiao Road, Jiangpu Street, Jiangbei New District, Nanjing, China